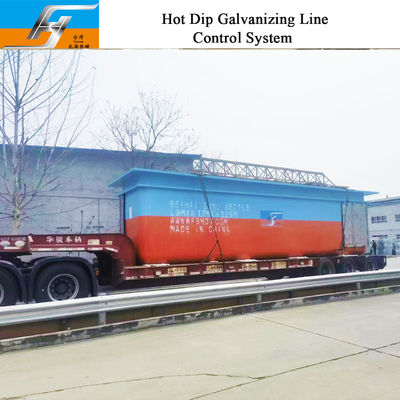

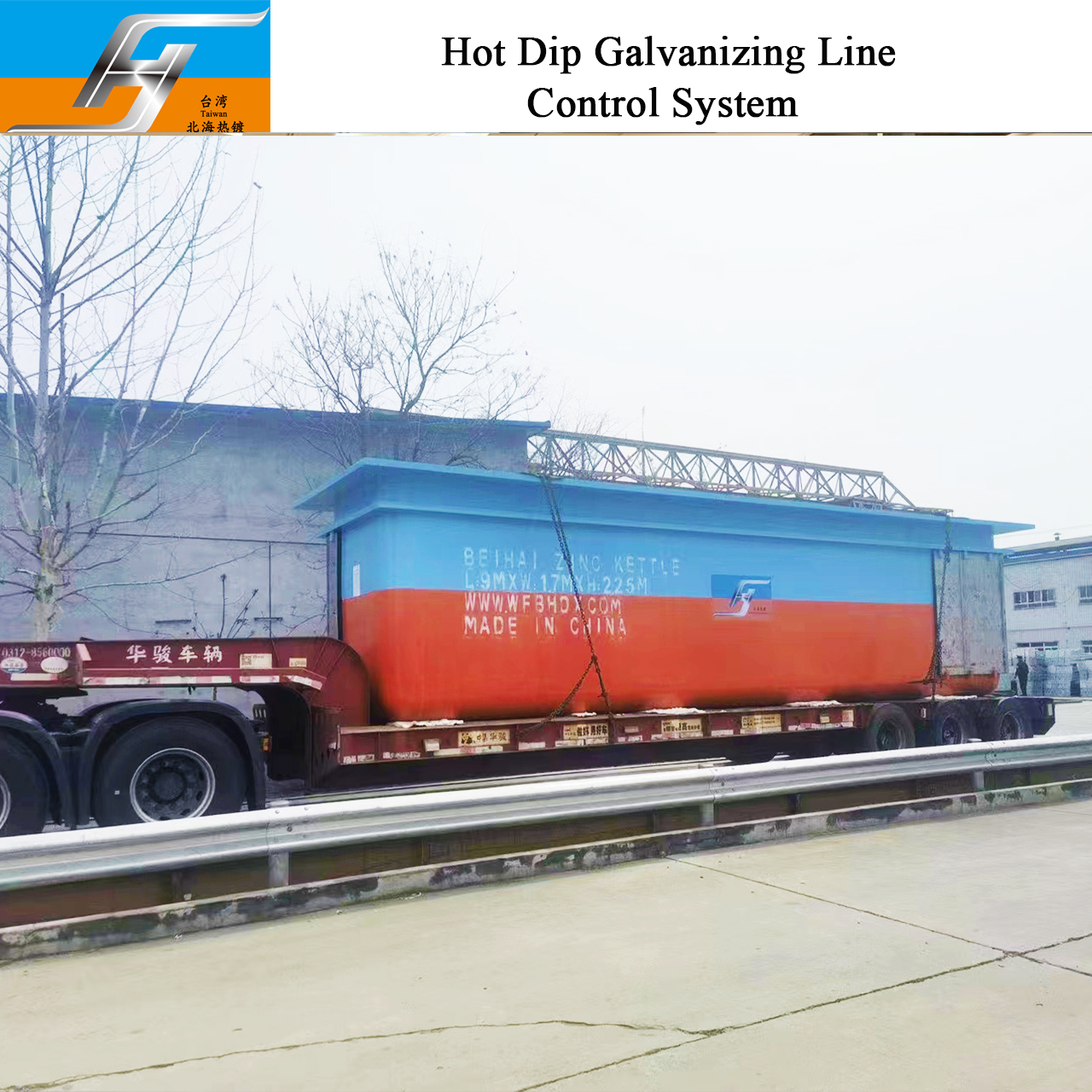

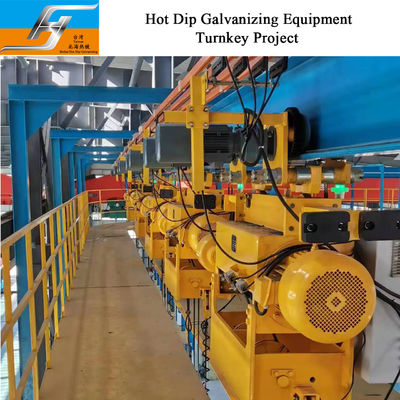

Why Choose Us

Beihai Galvanizing - Your trusted partner for customized galvanizing solutions. We deliver:

- Tailored factory designs to your exact specifications

- Comprehensive equipment solutions from A to Z

- Professional installation and commissioning services

- Ongoing technical support and after-sales service

Partner with us for a win-win future in galvanizing solutions!

Hot dip galvanizing knowledge sharing

Normal Temperature Range between 435 and 490 °C

In this temperature interval a very strong dependence of layer growth on the Si content of the steel is observed. Four typical galvanizing ranges exist (low-silicon, Sandelin, Sebisty and high-silicon), and all have significantly different coating thickness and structure.

Growth and structure of zinc coatings are influenced by hydrogen, which diffuses out, and thus indirectly by the Si content of the steel. Silicon impedes hydrogen effusion and determines the microstructure and character of the marginal zone in steel. Phosphor concentrates in steels through segregation

processes in the marginal zone and prevents the formation of a compact and dense δ1 phase, which becomes noticeable through strong layer growth, in particular in steels containing little silicon.

In the low-silicon range and in the Sebisty range above 450 °C, hydrogen indirectly impedes layer growth, because, due to delayed hydrogen effusion or delayed hydrogen postdiffusion through the reaction of the melt with the marginal zone of the steel,a dense δ1 phase can be formed. A gap between the steel and zinc coating develops clearly in the low-silicon range and slightly less so in the Sebesty range above 450 °C, because effusing hydrogen impedes layer growth by disturbing the phase-boundary bond. For this reason, a uniform cause for the parabolic growth in these two ranges can be assumed.

In particular, in the Sandelin range, where the formation of a δ1 phase hardly ever occurs and a dense δ1 phase never occurs, the hydrogen effusion promotes the layer growth, since the reactive surface is kept constantly active.

In the high-silicon range, the influence of hydrogen is only slightly noticeable. The silicon concentrating at the phase boundary in the course of the reaction, however, reduces the iron supply in the reaction zone. For this reason, the development of a continuous δ1 phase is no longer possible, and the rate of the galvanizing reaction increases strongly compared to the Sebisty range.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!